Product

The whole equipment is a cluster structure, which is composed of photoelectric conversion film deposition system, MAMS electronic stripping system, exhaust packaging system, getter material vacuum coating system and overall degassing system. Can realize the overall automatic coordination operation, can also be independent operation of each system, do not interfere with each other, can be set between the system interlock. 316 material manufacturing, reserved a number of flange interface.

View DetailsProduction-type TGV/TSV/TMV high-vacuum magnetron sputtering coating machine

Production-type TGV/TSV/TMV high-vacuum magnetron sputtering coating machine (Sputter-2000W series). This equipment is used for coating high-density through-holes and blind holes in glass and ceramic substrates, with an aspect ratio >10:1.

View DetailsMBE Molecular Beam Epitaxy Equipment

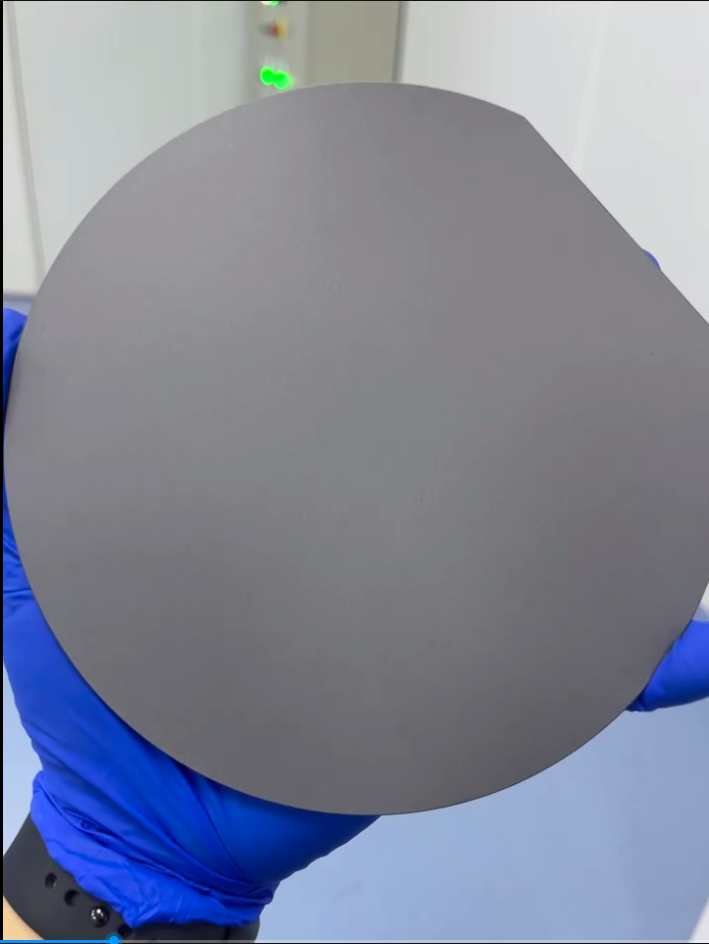

Molecular Beam Epitaxy (MBE) equipment can achieve epitaxial growth processes on certain substrates, enabling molecular self-assembly, superlattices, quantum wells, one-dimensional nanowires, and more. It can be used for process verification and the growth and manufacturing of epitaxial wafers for both second-generation and third-generation semiconductors. The MBE equipment provides an ultra-high vacuum environment during thin film epitaxial growth, creating an ideal setting for this process. It effectively eliminates various interference factors during film growth, resulting in high-precision thin films.

View DetailsHFCVD hot filament chemical vapor deposition equipment

Research and development design and manufacture of hot filament CVD diamond equipment, divided into experimental equipment and production equipment two categories. The equipment is mainly used for R & D and production of micro-crystalline and nano-crystalline diamond films. Can be used for mechanical level, thermal level, optical level, acoustic level of diamond products development and production. It can be used to manufacture large-size diamond polycrystalline wafers for high-power devices, high-frequency devices and heat sinks for high-power lasers.

View DetailsAbout Us

Pengcheng Semiconductor Technology (Shenzhen) Co., Ltd.

By the Harbin Institute of Technology (Shenzhen) and has many years of practical experience in the team of engineers to jointly initiate the creation.

Based on the intersection of technology frontier and market frontier, the company seeks innovation and sustainable development, solves the pain points of the industry and the problem of localization, and strives for the independent control of the industrial chain. The company's core business is micro-nano technology and high-end precision manufacturing, specific application areas include semiconductor materials, semiconductor technology and semiconductor equipment research and development design and manufacturing. The company's talent team has a complete knowledge structure, including a high-level material research and process research team with professors and doctors of Harbin Institute of Technology as the core, and a team of senior equipment designers from the industry. they have more than 30 years of experience in semiconductor material research, epitaxial technology research and semiconductor film preparation equipment design, production and manufacturing. Relying on Harbin Institute of Technology (Shenzhen), the company has advanced semiconductor R & D equipment platform and testing equipment platform, and can carry out scientific research work from a high starting point. Headquartered in Shenzhen, the company has the ability to develop, produce and debug semiconductor equipment, as well as pilot, production and sales of semiconductor materials and devices.

Further understandingCompany establishment time

technology patent

technology accumulation

Customer Service

Laboratory and R & D Center

Relying on the complete experimental platform and test analysis platform of Harbin Institute of Technology (Shenzhen), it provides support for R & D and production.

News

2026-01-05

Application of TGV Glass Through-Hole Technology in Magnetron Sputtering

2026-01-05

2025-12-16

Pengcheng Semiconductor: The Strategy, Tactics, and Survival Guide of a High-Tech Enterprise

2025-11-11