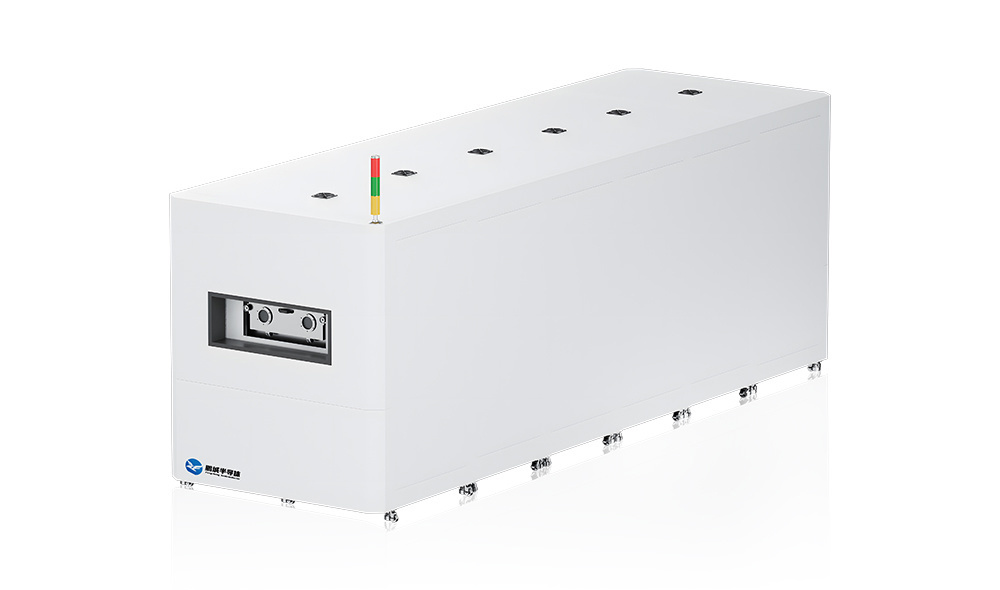

Production-type TGV/TSV/TMV high-vacuum magnetron sputtering coating machine

Production-grade TGV/TSV/TMV high-vacuum magnetron sputtering coating system (Sputter-2000W series): This equipment is used for depositing metal seed layers on glass substrates and ceramic substrates, enabling high-density through-holes and blind vias with a depth-to-diameter ratio exceeding 10:1.

- Product Description

-

Production-grade TGV/TSV/TMV High-Vacuum Magnetron Sputtering Coating System (Sputter-2000W Series) This equipment is used for depositing metal seed layers on high-density through-holes and blind holes in glass substrates and ceramic substrates, with aspect ratios exceeding 10:1. For example, it enables the deposition of Cu/Ti microstructures during substrate coating processes and dual-layer films of Au/TiW transmission lines, thereby providing critical support for enhancing the integration density of microsystems.

Advantages of this equipment: The film layer exhibits high uniformity and repeatability, with strong adhesion. The equipment features programmable, automated control based on the process formulation.

Equipment Structure and Performance Parameters

- Single-coating chamber, dual-coating chamber, multi-chamber coating chamber

- Horizontal structure, vertical structure

- Sample transfer: linear type

- Number and type of magnetron sputtering targets: multiple rectangular magnetron targets

- Magnetron sputtering targets: compatible with DC, RF, intermediate frequency, and high-energy pulsed modes

- The substrate is heatable, liftable, and can be biased.

- By introducing reaction gases, reactive sputtering deposition can be performed.

- Operation modes: manual, semi-automatic, fully automatic

- Substrate holder: Configured according to substrate size

- Substrate sizes: 2, 4, 6, 8, and 10 inches, as well as customer-specified dimensions.

- Maximum vacuum level in the sample introduction/extraction chamber: ≤8×10⁻⁸ Pa -5 Pa

- Working background vacuum level in the sample entry/exit chamber: ≤2×10 -3 Pa

- Ultimate vacuum of the coating chamber: 5 × 10 -5 Dad,

Working background vacuum level: 8 × 10 -4 Pa

- Film layer uniformity: <5% (in-wafer), <5% (inter-wafer)

- Overall leakage rate of the equipment: Vacuum level ≤ 10 Pa after 12 hours of shutdown.

Working conditionsType Parameter Note Power supply ~380V Three-phase five-wire system Power Configure according to device scale Coolant circulation Configure according to device scale Water pressure 1.0–1.5 × 10 5 Pa Cooling capacity Configure according to heat dissipation. Water temperature 18–25℃ Pneumatic component supply pressure 0.5 MPa to 0.7 MPa Gas supply pressure for the mass flow controller 0.05 MPa to 0.2 MPa Working environment temperature 10℃ to 40℃ Work environment humidity ≤50%

Key words:

Get Quote