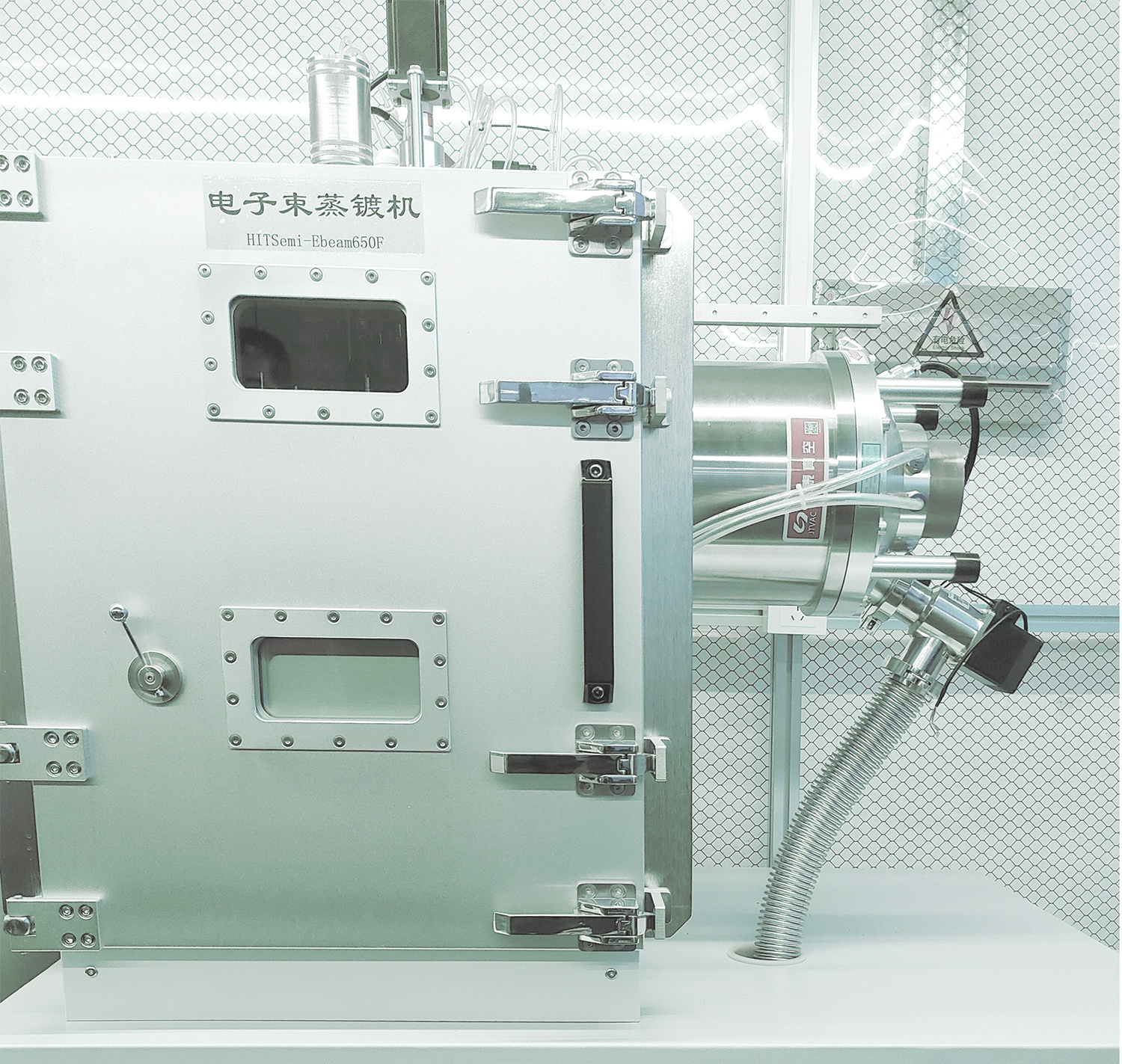

High-vacuum electron-beam evaporation coating machine

The high-vacuum electron-beam evaporation coating machine (PVD coating equipment) employs an electron-beam bombardment method under high-vacuum conditions to heat and vaporize materials, thereby depositing various metal films, oxide films, conductive films, optical films, semiconductor films, ferroelectric films, and ultra-hard films onto substrates. It can be used to deposit single-layer films, multilayer films, or doped films made of mixed materials, and is capable of coating a wide range of high-melting-point materials.

- Product Description

-

High-vacuum electron-beam evaporation coating machine (PVD coating equipment) Under high-vacuum conditions, a method is employed in which a material is heated and evaporated by bombardment with an electron beam, enabling the deposition of various metal films, oxide films, conductive thin films, optical films, semiconductor films, ferroelectric films, and ultra-hard films onto substrates. This technique allows for the deposition of single-layer, multi-layer, or doped films made from mixed materials, as well as a wide range of high-melting-point materials.

Suitable for production, scientific experiments, and teaching; can be custom-made according to user requirements.

Depending on user requirements, two types of automatic control systems can be optionally configured: an automatic control system for quartz crystal film thickness meters and an automatic control system for optical film thickness meters. By integrating a PLC with an industrial PC, the entire coating process can be fully automated, including functions such as monitoring the vacuum system, baking system, evaporation process, and film thickness. This approach significantly enhances work efficiency and ensures consistent and stable product quality.

Device features

The equipment features high vacuum degree, fast pumping speed, and convenient substrate loading and unloading. It is equipped with an E-type electron-beam evaporation source and a resistive evaporation source. With PID-controlled automatic temperature regulation, it offers advantages such as uniform film deposition, low outgassing, and even temperature distribution.

Vacuum performance

Ultimate vacuum: 7×10 -5 Pa~7×10 -6 Pa

Overall equipment leakage rate: 12-hour shutdown, ≤10 Pa

The recovery work vacuum time is short, and the atmospheric pressure reaches 7×10. -4 Pa ≤ 30 minutes;

Composition of the High-Vacuum Electron-Beam Evaporation Coating Machine (Electron-Beam Evaporation Coating Machine) Equipment Configuration

It consists of an E-type electron-beam evaporation gun, a resistive heating evaporation source assembly (optional), a sample mask baffle system, a vacuum generation system and a vacuum measurement system, a molecular pump vacuum unit or a cryogenic pump vacuum unit, a rotating substrate heating stage, a working gas supply line, a sample transfer mechanism, a film thickness control system, an electrical control system, and a constant-temperature cooling water system, among other components.

Optional accessories: Film thickness monitor, constant-temperature cooling water tank.Optional: Coating machine + Glove box

Types and Configurations of Thermal Evaporation SourcesProject

Parameter

Note

E-type electron beam evaporation system 1 set Power 6 kW to 10 kW Other power options (available upon customer request) Crucible 1 to 8 animals Can be optionally equipped according to user requirements. Resistive Thermal Evaporation Source Assembly 1 to 4 sets (Can be equipped according to user requirements) Types of Resistive Thermal Evaporation Sources

- Tantalum (tungsten or molybdenum) metal boat thermal evaporation source assembly

- Quartz boat thermal evaporation source assembly

- Tungsten electrode or tungsten blue thermal evaporation source assembly

- Tantalum furnace thermal evaporation source assembly (with boron nitride crucible or ceramic crucible)

- Source furnace thermal evaporation assembly (with quartz crucible or boron nitride crucible)

Operation method

Manual, semi-automatic

Research-oriented cabinet-type integrated high-vacuum electron-beam evaporation coating machine

Key words:

Get Quote