High vacuum resistance thermal evaporation coating machine

- Product Description

-

High vacuum resistance thermal evaporation coating machine (PVD coating equipment)Using resistance thermal evaporation technology, it is under high vacuum conditions, by heating the material method, on the substrate deposition of various compounds, mixtures of single-layer or multi-layer film. Can be used for production and scientific experiments, can be customized according to user requirements; can be used for the physical and chemical research of materials; can be used for the preparation of metal conductive electrode; can be used for the physical and chemical properties of organic materials research experiments, the principle of organic semiconductor devices research experiments, OLED experimental research and organic solar thin film cell research experiments.

Equipment composition

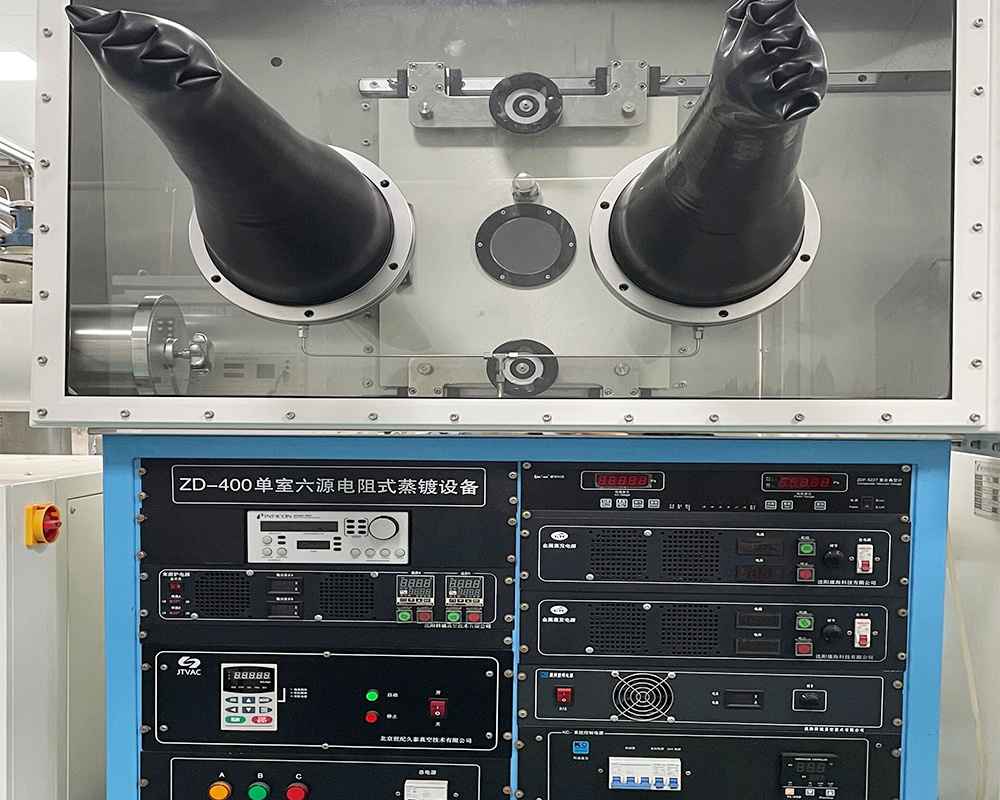

-Single coating room

-Single coating chamber + injection chamber

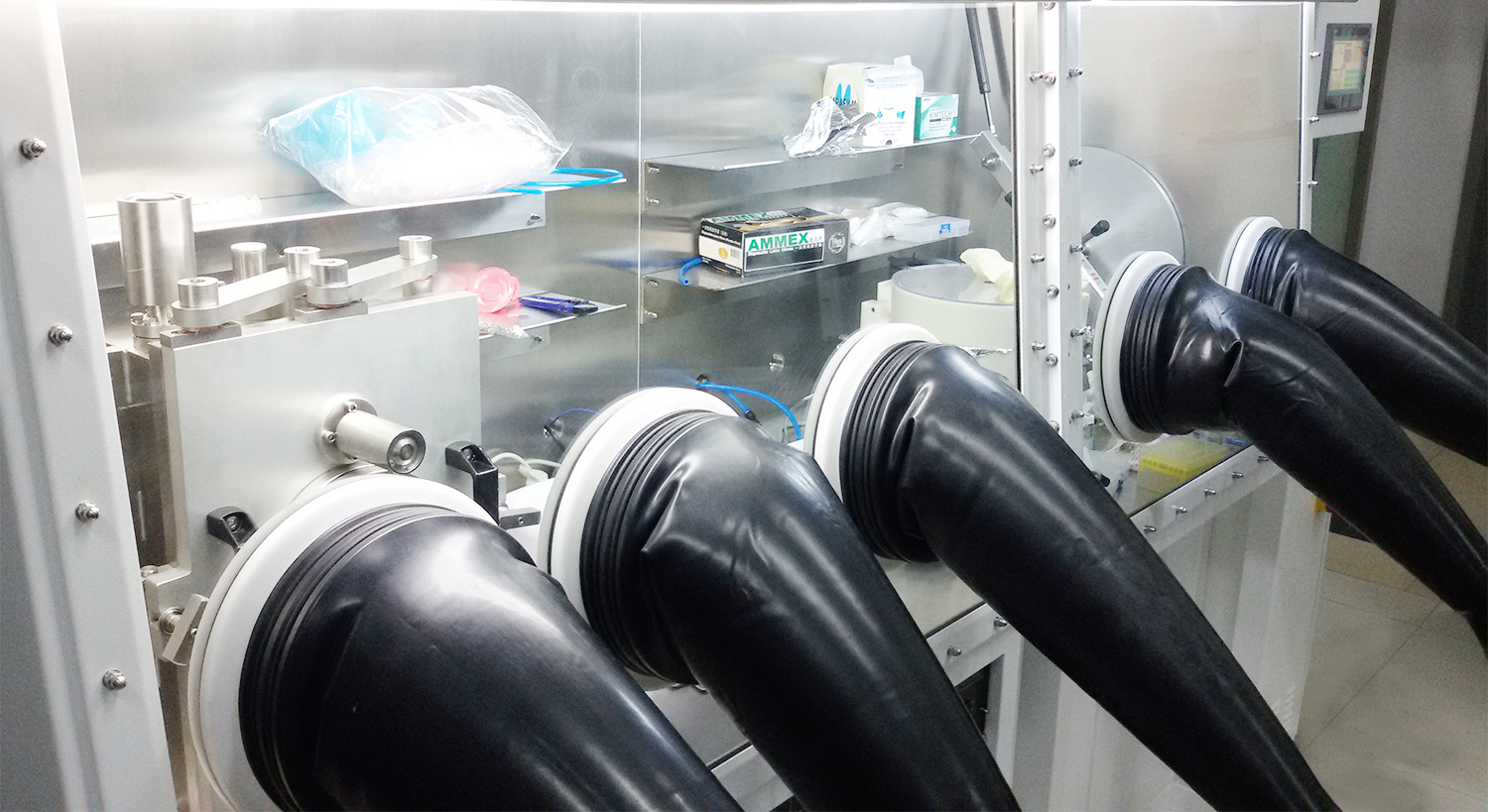

-Single coating room + glove box (the coating room can be placed in the glove box)

-Single coating chamber + injection chamber + glove box (the coating chamber can be placed in the glove box)

-Multi-coating chamber + sample transfer chamber + glove box (cluster structure, sample transfer using vacuum manipulator)

Equipment composition

Resistance thermal evaporation source assembly, sample mask baffle system, vacuum acquisition system and vacuum measurement system, molecular pump (or cold pump) vacuum unit, rotating substrate heating table, working gas circuit, glove box connecting parts, sample transfer mechanism, film thickness control system, electric control system, constant temperature cooling water system, etc.

The type and number of thermal evaporation sources can be configured according to user needs.

Optional: film thickness monitor, constant temperature refrigeration water tank.

Types and Configuration of Thermal Evaporation Source

Resistance thermal evaporation source components: quantity: 1~12 sets (can be equipped according to user requirements);

Resistance thermal evaporation source types: tantalum (tungsten or molybdenum) metal boat thermal evaporation source components, quartz boat thermal evaporation source components, tungsten or tungsten blue thermal evaporation source components, tantalum furnace thermal evaporation source components (with boron nitride crucible or ceramic crucible), beam source furnace thermal evaporation components (with quartz crucible or boron nitride crucible).

High vacuum resistance thermal evaporation coating machine

Working conditions (the working conditions of the equipment that the laboratory should have)

Power supply: 4kW, three-phase five-wire system ~ AC 380V

Working environment humidity: 10 ℃ ~ 40 ℃

Working environment temperature: ≤ 50%

Cooling circulating water: 0.2m3/h, water temperature 18 ℃ ~ 25 ℃

Water pressure: 0.15MPa ~ 0.25MPa

Vacuum performance

Ultimate vacuum: 7 x 10-5Pa ~ 7 × 10-6Pa

Overall leakage rate of equipment: 12 hours of shutdown, ≤ 10Pa

Operation mode

Manual, semi-automatic

Production magnetron sputtering ion beam multi-arc coating machine

Production magnetron sputtering and ion beam coating machine

Scientific research cabinet type integrated high vacuum thermal evaporation coating machine

Key words:

Get Quote