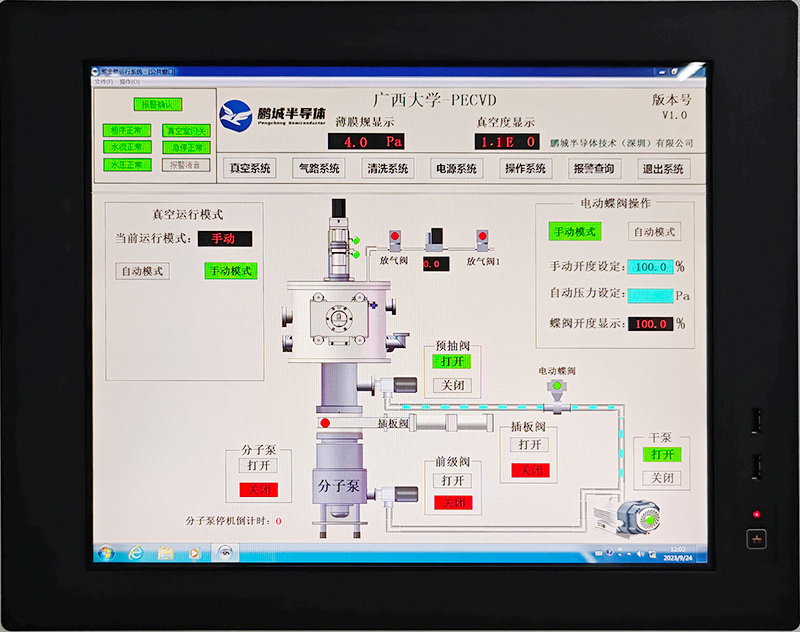

PECVD plasma enhanced chemical vapor deposition equipment

PECVD plasma enhanced chemical vapor deposition equipment is mainly used for silicon nitride and silicon oxide film growth in a clean vacuum environment; using single-frequency or dual-frequency plasma enhanced chemical vapor deposition technology, it is an ideal process equipment for depositing high-quality silicon nitride, silicon oxide and other thin films.

- Product Description

-

PECVD plasma enhanced chemical vapor deposition equipmentIt is mainly used for thin film growth of silicon nitride and silicon oxide in a clean vacuum environment; using single-frequency or dual-frequency plasma enhanced chemical vapor deposition technology, it is an ideal process equipment for depositing high-quality silicon nitride, silicon oxide and other thin films.

Equipment use and functional characteristics

1. The equipment is a high vacuum single frequency or dual frequency plasma enhanced chemical vapor deposition PECVD thin film equipment, mainly used for the preparation of silicon nitride and silicon oxide films.

2, equipment protection function is strong, with vacuum system detection and protection, water pressure detection and protection, phase sequence detection and protection, temperature detection and protection.

3. Configuration of tail gas treatment device.

Equipment safety design

1. Detection and protection of power system

2. Set up vacuum detection and alarm protection function

3. Temperature detection and alarm protection

4. Pressure detection and flow detection and alarm protection of cooling circulating water system

Technical indicators of equipment

Type

Parameters

Sample size ≤ φ8 inches (or multiple pieces of 2 inches) Sample heating table heating temperature Room temperature ~ 600 ℃ ± 0.1 ℃ Ultimate vacuum of vacuum chamber ≤ 3 × 10-5Pa Working background vacuum ≤ 4 × 10-4Pa Overall leakage rate of equipment After stopping the pump for 12 hours, vacuum degree ≤ 10Pa Sample, electrode spacing 5mm ~ 50mm online adjustable Working control pressure 10Pa ~ 1500Pa gas control loop Configuration according to process requirements Frequency of single frequency power supply 13.56MHz Frequency of dual frequency power supply 13.56MHz/400KHz Working conditions

Type

Parameters

Power supply Three-phase five-wire AC 380V Working environment temperature 10 ℃ ~ 40 ℃ Gas supply pressure of gas valve 0.5MPa ~ 0.7MPa Mass flow controller input pressure 0.05MPa ~ 0.2MPa Cooling water circulation 0.6 m3/h water temperature 18 ℃ ~ 25 ℃ Total power of equipment 7kW Equipment floor area 2.0m ~ 2.0m Single-chamber and multi-chamber PECVD equipment

Key words:

Get Quote