LPCVD Low Pressure Chemical Vapor Deposition Equipment

LPCVD low-pressure chemical vapor deposition equipment (research-type LPCVD) is the deposition of various functional films (mainly Si3N4, SiO2 and Poly silicon films) on the substrate by chemical reaction vapor phase epitaxy under the condition of low pressure and high temperature. Can be used for scientific research, practical teaching, small device manufacturing.

- Product Description

-

LPCVD Low Pressure Chemical Vapor Deposition Equipment (Research LPCVD)Under the condition of low pressure and high temperature, various functional films (mainly Si3N4、 SiO2and Poly silicon film). Can be used for scientific research, practical teaching, small device manufacturing.

Equipment structure and characteristics

1, miniaturization, convenient laboratory operation and use, greatly reduce the cost of experiments

Two kinds of substrate size 2 inches or 4 inches; each time 1~3 pieces.

Substrate placement mode: three kinds of substrate carriers are configured, vertical, horizontal and inclined.

Substrate shape type: irregular shape of the scattered piece, φ2~4 inch standard substrate.

2. The equipment is horizontal pipe structure

It is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum system, gas circuit system, temperature control system, pressure control system and gas cylinder cabinet.

The reaction chamber is made of high-purity quartz, which is corrosion-resistant, anti-pollution, low leakage rate and suitable for high-temperature use. The electronic control part of the equipment adopts advanced detection and control system, with accurate measurement, stable and reliable performance.

LPCVD equipment main technical indicators

Type

Parameters

Film-forming type You are.3N4、 Poly-Si 、 SiO2Wait Maximum temperature 1200 ℃ Length of constant temperature zone Configure according to user needs Temperature control accuracy of constant temperature zone ≤ ± 0.5 ℃ Working pressure range 13~1330Pa Film non-uniformity ≤ ± 5% Number of substrates per load Standard substrate: 1~3 pieces; irregular size scattered pieces: several Pressure control Closed Loop Inflatable Control Loading method Manual sample entry and exit LPCVD Low Pressure Chemical Vapor Deposition Equipment (Production LPCVD)

Device function

The equipment is under the condition of low pressure and high temperature, by chemical reaction vapor phase epitaxy method on the substrate deposition of various functional films (mainly Si3N4, SiO2 and Poly silicon film).

The relevant coating process can be provided.

Equipment structure and characteristics:

The equipment is a horizontal tube horizontal structure, which is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum system, gas circuit system, temperature control system, pressure control system and gas cylinder cabinet.

The reaction chamber is made of high-purity quartz, which is corrosion-resistant, anti-pollution, low leakage rate and suitable for high-temperature use. The electronic control part of the equipment adopts advanced detection and control system, with accurate measurement, stable and reliable performance.

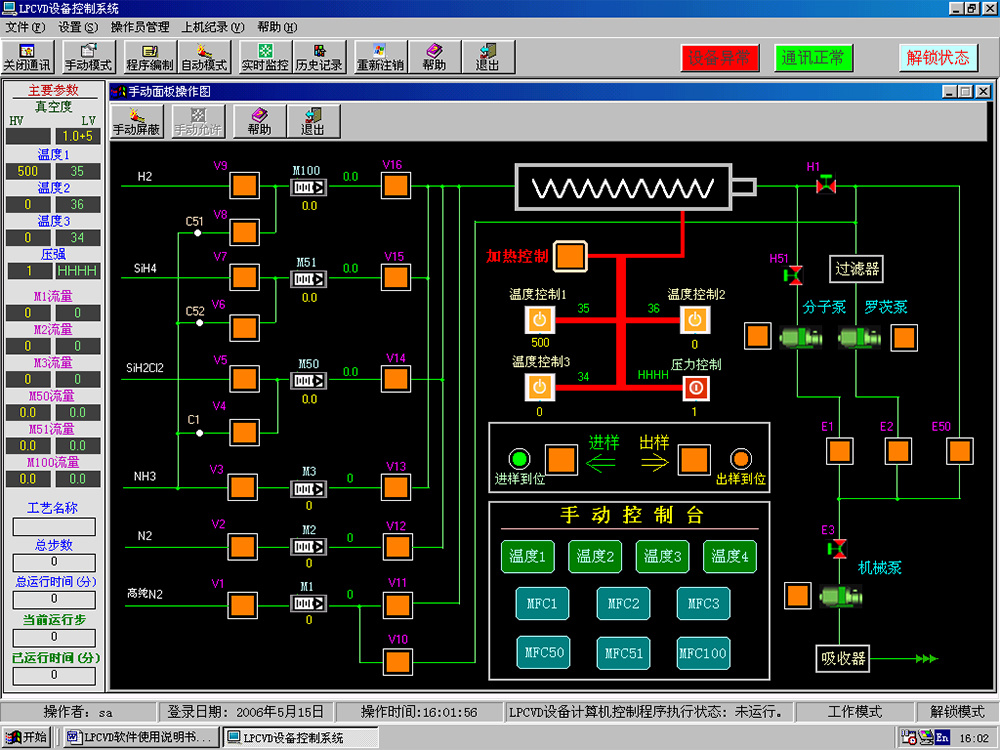

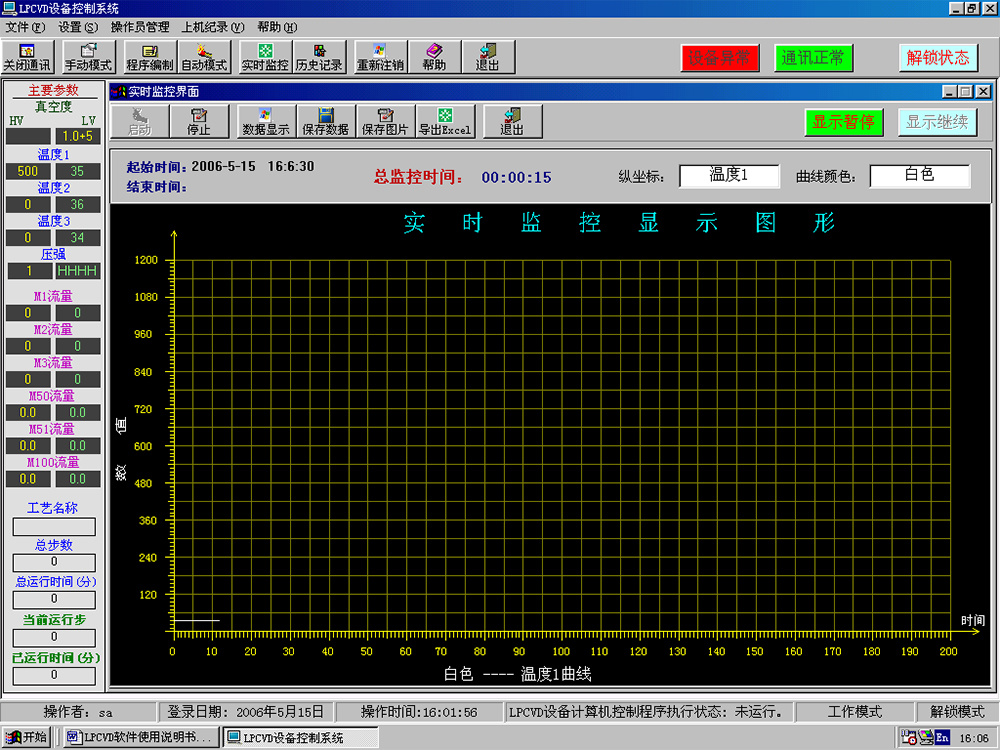

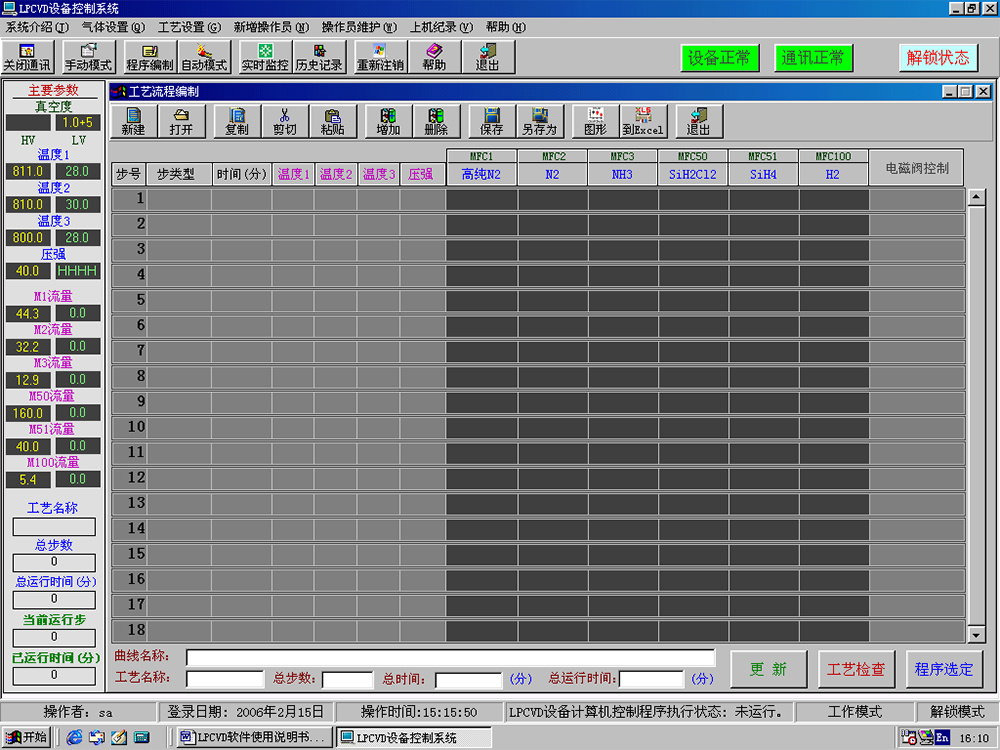

The whole process is managed by the computer, and the process parameters such as furnace temperature, gas flow, pressure, valve action, pump opening and closing are monitored and automatically controlled. It can also be controlled manually.

Main technical indicators of equipmentType

Parameters

Film-forming type You are.3N4、 Poly-Si 、 SiO2Wait

Maximum temperature 1200 ℃ Length of constant temperature zone Configure according to user needs Temperature control accuracy of constant temperature zone ≤ ± 0.5 ℃ Working pressure range 13~1330Pa Film non-uniformity ≤ ± 5% Number of substrates per load 100 tablets Total power of equipment 16kW Amount of cooling water 2m3/h Pressure control Closed Loop Inflatable Control Loading method Cantilever Boat Automatic Sample Delivery LPCVD software control interface

LPCVD manual operation interface

LPCVD real-time operation monitoring interface

LPCVD automatic operation interface

LPCVD process preparation interface

Key words:

Get Quote