Features and functional advantages of plasma coating instrument

Plasma coating instrument is a kind of surface treatment equipment, which has a wide range of applications and important functional advantages. It is mainly used for surface coating and modification treatment. By exposing the material to a plasma environment, the modification and coating of the material surface can be achieved by utilizing the mechanisms of ion bombardment and reactive deposition. This technology has a wide range of applications in various industries, such as electronics, optoelectronics, medical, automotive and other fields.

2024/08/12

The use of magnetron sputtering coating instrument and matters needing attention

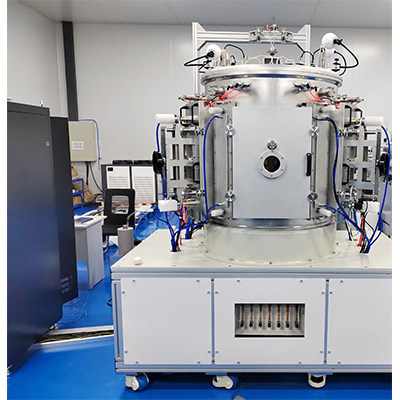

Magnetron sputtering coating instrument (PVD coating equipment) is a common surface coating equipment. It is a technology that uses evaporation or sputtering to deposit thin films on the surface of a substrate under vacuum conditions to prepare metals, alloys, compounds, semiconductors, ceramics, dielectric composite films and other chemical reaction films. It is suitable for plating various single-layer films, multi-layer films, doped films and alloy films, and can be used for plating magnetic materials and non-magnetic materials. Widely used in electronics, optoelectronics, optics, medical and other industries. In order to ensure its normal use and obtain a good coating effect, the following are some details and techniques that need to be paid attention to when using the magnetron sputtering coating instrument.

2024/07/29

As an ultra-wide bandgap semiconductor material, diamond has excellent physical properties such as high carrier mobility, high thermal conductivity, high breakdown electric field, high carrier saturation rate and low dielectric constant, and is considered to be the "ultimate semiconductor" for the preparation of the next generation of high power, high frequency, high temperature and low power loss electronic devices ".

2024/07/22

Definition and function of magnetron sputtering coating instrument

Magnetron sputtering coating instrument (PVD coating equipment) is an advanced surface treatment equipment, which has the characteristics of high efficiency. By using the magnetic field to control the motion trajectory of the ion beam, the sputtering adhesion to the surface of the material is achieved, so as to obtain high-quality thin film coating. The main function of the magnetron sputtering coater is to form a uniform, dense and good adhesion film layer on the surface of different materials to improve the hardness, wear resistance and corrosion resistance of the material. At the same time, it can also be used to change the optical properties, electrical properties and thermal conductivity of materials to meet the needs of different fields.

2024/07/17

Diamond is a typical multi-functional limit material, which has excellent properties in electrical, optical, thermal, mechanical acoustics and electrochemistry, and has broad application prospects in many high-tech fields.

2024/07/09

Application of PVD Technology in Semiconductor Devices

In the rapidly developing field of semiconductor technology, physical vapor deposition (PVD) is a key tool to achieve the accuracy and efficiency of thin film deposition processes. Let's take a look at the advanced applications of PVD technology in the semiconductor industry.

2024/07/04

Shenzhen CVD diamond film technology [Typhoon News]]

CVD diamond film technology has been applied to many fields because of its excellent performance and wide application prospect. In the future, with the progress of technology and the continuous optimization of performance, CVD diamond film has a broader application prospect in the following fields:

2024/04/22

PVD vacuum coating equipment industry analysis

In 2024, the total size of the global PVD vacuum coating equipment industry is about $2.2 billion, and it is expected that this figure will double to $4.7 billion by 2024. PVD vacuum coating technology is formed by non-metallic substances with vacuum temperature and charged ion collision technology to form thick film, which has the advantages of high polymerization, strong adhesion, high transparency and good corrosion resistance.

2024/03/04

Market status of vacuum coating industry

Vacuum coating is a branch of surface treatment technology, which refers to the process of converting metal, non-metal or compound materials (film materials) into gaseous or plasma state by physical or chemical means in order to reduce the interference of impurities. and deposited on the surface of glass, metal, ceramic, plastic or organic materials and other solid materials (referred to as substrates, substrates or substrates) to form a thin film.

2024/02/28

What is chemical vapor deposition (CVD) technology?

Chemical vapor deposition (CVD) technology is used to prepare high-purity, high-performance solid thin films of the main technology, is committed to integrated circuits, semiconductor lighting, MEMS, power semiconductors, compound semiconductors, new energy photovoltaic and other fields to provide various types of CVD equipment to meet the needs of customers a variety of manufacturing processes.

2024/01/29

![Shenzhen CVD diamond film technology [Typhoon News]] Shenzhen CVD diamond film technology [Typhoon News]]](https://omo-oss-image.thefastimg.com/portal-saas/pg2024090313222616725/cms/image/cc3c3362-cba6-4927-9837-fe10be1f2668.jpg)